Product Details

Product Introduction

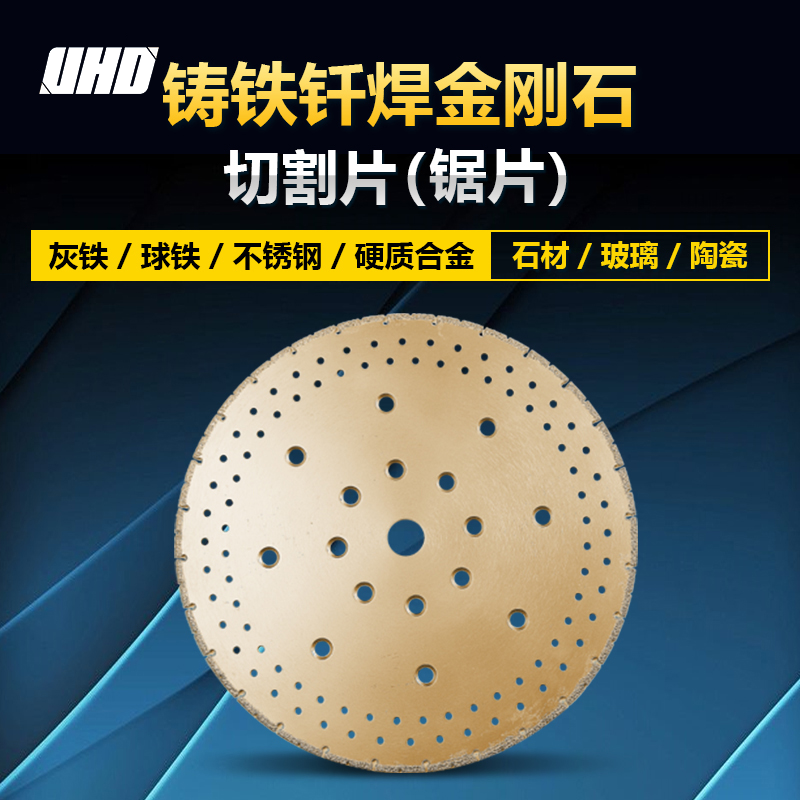

Developed and manufactured by Henan UHD Superhard Tools Co., Ltd. (UHD), the UHD superhard 400H brazed diamond saw blade is specifically designed for demanding industrial cutting applications. It utilizes carefully selected, high-quality diamond micro-particles, combined with an advanced brazing process, to ensure a secure cutter grain, significantly enhancing wear resistance and longevity. With a diameter of 400 mm, the blade is compatible with a wide range of handheld and benchtop cutting equipment, suitable for both wet and dry cutting of hard materials such as granite, marble, concrete, and tile. A unique heat sink design optimizes the cutter head structure, effectively reducing vibration and noise for safe and comfortable operation. CE-certified, it also supports customization to meet the individual needs of diverse customers. Backed by stringent quality management and robust R&D capabilities, UHD provides professional after-sales technical support and repair services to customers worldwide, ensuring efficient and stable industrial production. Choosing the UHD superhard 400H diamond saw blade ensures high efficiency, durability, and precise cutting.

Advantages and features

1. High-strength brazing technology ensures secure attachment of diamond particles, enhancing wear resistance and service life. 2. Unique heat sink design effectively reduces blade operating temperature and improves cutting efficiency. 3. Optimized cutter head structure reduces vibration and noise, ensuring safety and comfort during cutting. 4. Compatible with a variety of handheld and desktop cutting equipment for wide applicability. 5. CE certified for quality assurance and customizable to meet diverse needs. 6. Professional after-sales technical support and repair services ensure a worry-free user experience.

Application Scenario

Widely used for wet and dry cutting of hard building materials such as granite, marble, concrete, and tiles, it is ideal for construction, stone processing, road engineering, and heavy-duty industrial cutting operations. Targeting the global market, it is particularly well-suited for professional cutting companies, stone processing plants, and engineering contractors who require highly wear-resistant, high-efficiency cutting tools.