Product Details

Product Introduction

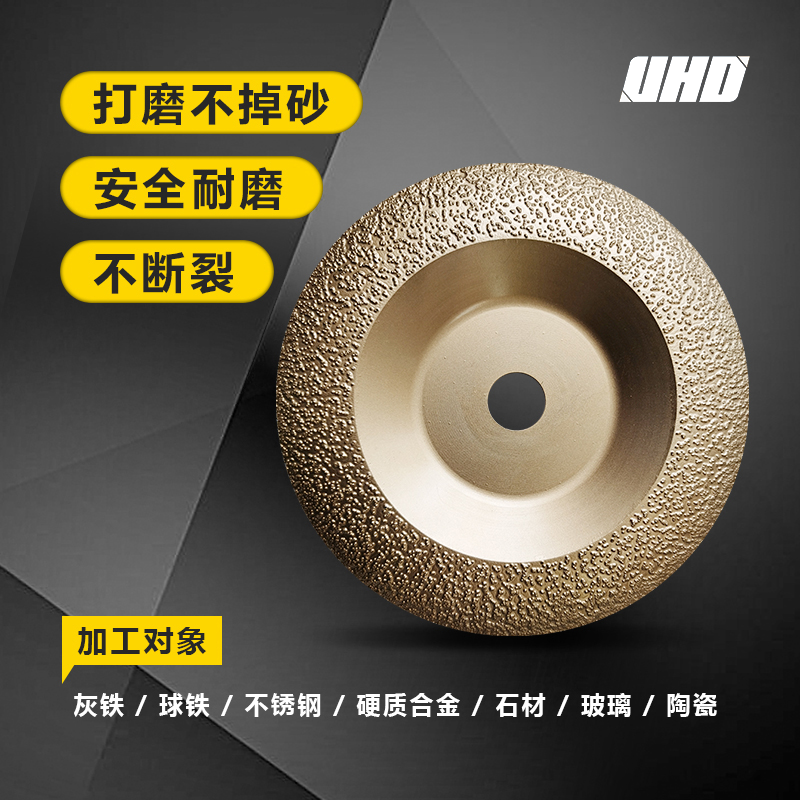

Henan UHD Superhard Tools Co., Ltd. professionally offers 125mm high-wear-resistant brazed diamond grinding discs, crafted using advanced brazing technology and high-quality diamond particles. Designed specifically for high-intensity industrial grinding, these discs boast excellent wear resistance and impact resistance, ensuring long service life and stable operating results. Supporting various flat and curved surfaces, they are widely applicable to the precision machining of a variety of materials, including ceramics, glass, cemented carbide, gray cast iron, and stainless steel. UHD strictly adheres to the ISO9001 quality management system, providing comprehensive technical support and professional after-sales service, committed to creating efficient and reliable superhard material grinding tools for global customers. Whether for stone finishing or metal precision machining, these grinding discs meet demanding industrial application requirements, helping customers improve production efficiency and processing quality.

Advantages and features

1. Advanced brazing technology is used to achieve a strong bond between diamond particles and the metal matrix, improving wear resistance and service life.

2. Impact-resistant design ensures stable and safe operation of the grinding disc even under high-intensity loads.

3. Multiple specifications and shapes are available to meet the processing needs of flat surfaces and complex curved surfaces.

4. Wide range of applications, supporting fine grinding of ceramics, glass, cemented carbide and various metal materials.

5. Strictly implement the ISO9001 quality management system to ensure the stable and reliable quality of every product.

6. We offer customized services to meet the diverse and personalized processing needs of our clients.

Application Scenario

Suitable for industrial grinding of materials such as ceramics, glass, cemented carbide, gray cast iron, ductile cast iron, stainless steel, and stone. Widely used in metal processing, stone finishing, machinery manufacturing, mold making, and high-strength grinding. This product is targeted at metal processing plants, stone processing companies, and precision manufacturers worldwide, helping to improve processing efficiency and product precision.

.png?x-oss-process=image/resize,m_fill,h_300,w_300/format,webp)